Custom DIN Rail Mounting Plates

Need a Custom DIN Plate?

Do you need to mount to DIN rail, but need something a little different than what we offer in stock? We can build custom DIN Plates of various materials and with multiple mounting options.

Details

In general, it works best when the customer needs more than just a couple pieces; depending on the product, approximately 20 pieces minimum is a decent rule of thumb. In this way, the effective 'per piece' cost can be kept relatively low.

We can offer Plates cut to your specifications with material options of Aluminum plate, sturdy FR4 material, or Polycarbonate. Custom mounting hole options include through-hole, threaded, and/or installed broaching nuts. The DIN clips that are mounted on the back of the plates come in varying sizes, and we also have right angle clips available -- a great DIN rail space saving option!

Please contact us if we can be helpful in your next project. There is no charge for consultations.

See below for our process from start to finish.

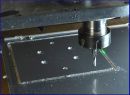

Milling

During the milling process, the mounting holes are routed and the plates are cut out to your required size.

Finishing

Aluminum Plates will be surface finished to ensure a uniform face and smooth edges.

Cleaning

Plates are cleaned to remove dust and chips created during the fabrication process.

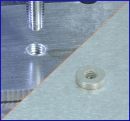

Tapping or Threaded Nuts

For Aluminum Plates, we have the ability to thread the mounting holes. For all material options, we offer a selection of threaded broaching nuts to be installed in desired locations.

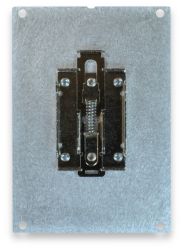

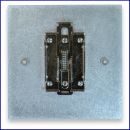

Clip Installation

The DIN Clip is installed and the assembly is complete!

Getting Started

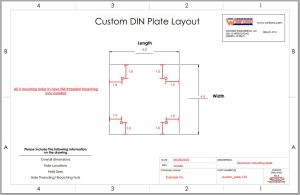

Please download and use our Custom DIN Rail Mounting Plate drawing template to illustrate your dimensions and mounting hole requirements. Alternatively, if your required design is similar to one of our stocked products, feel free to download that drawing from the product's webpage and mark up the necessary additions and/or changes. You can also reference our Template Example below.Contact us today to discuss your requirements.

-

Email: sales@winford.com

Phone: 1-877-634-2673

Click image to enlarge.

Click image to enlarge.